Inside this issue

FROM THE EDITORS

COVER STORY

IN THE NEWS

- Ørsted Takes Step With Carbon Capture

- Arbor Gas Inches Closer To Port Allen

- Enviva Names Meth As President

- Enviva Recognizes Port Of Pascagoula

- MDF Or Bioenergy For Roseburg?

- Ruling Stalls Oregon Counties

- Well Known Timber Firm To Build Sawmill

- Deere Announces New Forestry President

- Price Becomes 75th FPS President

Equipment Companies Reveal Latest Developments

EDITOR’S NOTE: This is the second of three parts in the coverage of the Wood Bioenergy Conference & Expo held March 29-30, 2022 at the Omni Hotel at CNN Center and hosted by Wood Bioenergy magazine. Part one in the June issue focused on the keynote talks from producer and consultant personnel. Part two highlights several presentations delivered by representatives of equipment and technologies companies. Look for part three in the October issue.

ENERGY TECHNOLOGY

EDITOR’S NOTE: The following companies submitted editorial profiles to complement their advertisements placed in Wood Bioenergy August 2022.

- Baker-Rullman

- Biomass Engineering & Equipment

- Buettner Energy Systems

- Hurst Boiler

- Mid-South Engineering

- MoistTech

- Player Design Inc.

PRODUCT NEWS

- Stela Celebrates 100th Anniversary

- Elmia Wood Back On Track

- ‘Strongest Link To Success’

- TEC Is Named Sennebogen’s Best

Find Us On Social

From the Editors

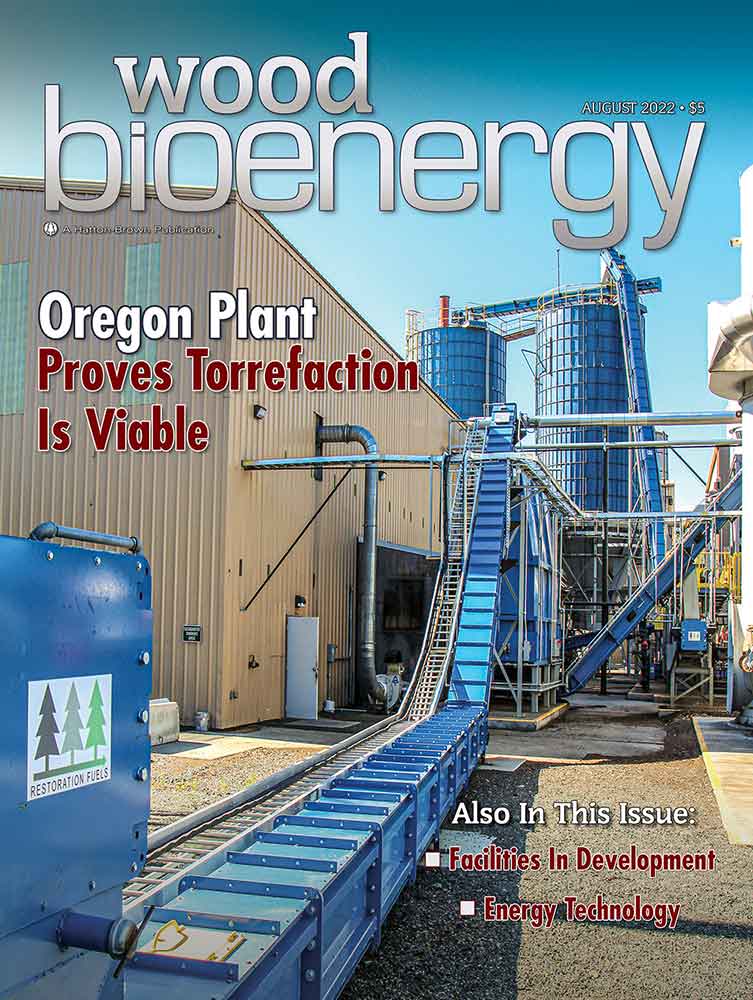

Restoration Fuels Offers Torrefaction Solution

Forest health projects that seek to reduce fuel loads generally work to thin out timber stands and convert to more open landscapes that are more resilient to wildfire. The biggest issues are on public lands in the U.S. West, where timberland managers have been using “stewardship” contracts that are different than traditional timber sales and instead try to address forest conditions over a larger area or in conjunction with other management activities to achieve specific management results.

This generally means thinning timber and removing brush. What this nets the stewardship contract purchaser are products that include a measure of sawlog or solid wood product-sized timber, but also a lot of lowvalue biomass that starts adding to costs as soon as it’s picked up and moved to the landing.

In 2014, officials with the U.S. Endowment for Forests & Communities saw an opportunity to pursue its goal of supporting rural communities through expanded wood utilization, and began an R&D process that resulted in the establishment of Restoration Fuels and a torrefied biomass plant that started up in 2021.

Make an announcement that you’re auctioning off ponderosa pine sawlogs and you’ll usually draw a crowd. Tell them the logs come with five or 10 times as much biomass tonnage that must also be removed and the crowd gets a good bit smaller.

Restoration Fuels located the new plant adjacent Malheur Lumber Co. in John Day, Ore., where the Malheur National Forest that surrounds the town is finishing up a 10-year forest stewardship contract and looking to award a similar contract next year.

Since the contract was awarded in 2013 to local contractor Iron Triangle, more than 55,000 acres have been treated to reduce wildfire risk and more than 140,000 acres of wildlife habitat have seen restoration activities.

From Left: Jessica Johnson, Managing Editor; Dan Shell, Senior Editor; Rich Donnell, Editor-in-Chief; David Abbott, Senior Associate Editor

To boost local markets, Malheur Lumber added a small log processing line to handle the small logs produced by the contract, and Iron Triangle started up a post and pole plant to handle smaller and shorter solid wood material. Restoration Fuels is still ramping up production, but the value the operation provides in the overall local forest health equation and solution is key.

Wood Bioenergy has covered the efforts to improve forest health on Arizona national forests through the stewardship process and the big concept 4 Forests Restoration Initiative. The lack of markets for biomass continues to pose a challenge when it comes to racking up the acres treated.

Restoration Fuels officials thought they’d have a ready-made market for their torrefied product with a converted power plant in Boardman, Ore., but the utility chose a complete decommission instead. The change has company officials looking at different products and markets than just fuel.

The plant is proving that torrefaction is a viable conversion process, with reduced carbon footprint thanks to using syngas produced as a process fuel. Especially promising is the development of high carbon content material (80%+) as plant operators are learning more about tuning the system for custom carbon percentages.

Restoration Fuels is still basically just getting started, but it is providing a scalable solution to issues associated with biomass handling and removal that have made forest health challenges so difficult in some areas.

Though not a one-size-fits-all solution, the Restoration concept can be adapted to different projects in other locations, officials believe.

Cover Story: Oregon Plant Proves Torrefaction Is Viable

Article by Dan Shell, Senior Editor, Wood Bioenergy

JOHN DAY, Oregon – Restoration Fuels is proving that torrefaction technology is a viable option for converting lower value biomass and mill residuals into higher value carbon products for fuel and other applications. The concept is especially important here in John Day, where the Malheur National Forest surrounding town has almost completed a first major 10-year forest health stewardship project and will soon embark on another.

Such projects generate sawlogs as well as lots of small diameter volume that includes post, pole and firewood material, and biomass. According to project task orders, all material needs to be removed to thin landscapes into more historically open and pine-dominant timber stands with reduced fuel loads that are more resistant to fire.

Advanced torrefied materials like this 80%+ carbon content product have the potential to open new markets and applications.

Finding markets and outlets for the low value material is key to the success of such projects, which are being implemented across the Western U.S. where public lands are increasingly hard hit by wildfire. Officials with Restoration Fuels believe their high carbon torrefied system can be transferred to other projects as well.

As a fully-owned subsidiary of the U.S. Endowment for Forestry and Communities, the plant was created in response to all of the above and to help fulfill the Endowment’s mission to support rural economies while boosting forest health and promoting wood utilization by creating leading edge high carbon fuels and materials.

The Restoration Fuels story originally began in 2014 with that objective in mind and worked with multiple groups and organizations including the USDA Consortium for Advanced Wood-to-Energy Solutions (CAWES) formed by the U.S. Forest Service (FS) and the Endowment. According to Restoration Fuels CEO Matt Krumenauer, the FS played a big role in bringing together a wide variety of stakeholders on the wood bioenergy issue, including seven higher education institutions, the USFS Forest Product Laboratory, plus large private timberland owners, forest products producers and technology vendors. The group focused on cooperative basic research and technologies and ways to accelerate commercialization.

Officials believe the process can work in areas needing forest health work but lacking markets for biomass.

Torrefaction and high carbon torrefied biomass material were identified as a technology and product that require less advanced research and also deliver an end product that can be used in a variety of applications, from high carbon sustainable fuel to soil treatments and much more.

Torrefaction is the roasting of wood in a high temperature, low-oxygen environment, resulting in a biomass product that has a higher carbon density. Restoration Fuels also re-burns the syngas from the torrefaction reaction, almost eliminating process heating fuel demand and further reducing the facility’s carbon footprint.

Construction on the plant began in 2019. It was sited at the back end of the Malheur Lumber Co. facility, near the sawmill’s chipping operations. Officials with Malheur Lumber, which has added small log processing equipment to handle material coming from local forest health projects, have been supportive of Restoration Fuels since the beginning. The plant began testing production capability in late 2021. Equipment has been a mix of mostly used and some new. Key pieces include Hurst Boiler, a low temperature belt dryer, Sensortech moisture meters, Biomass Engineering & Equipment (BE&E) conveyors and material handling, Clarke’s spark detection system, Coen burners and C.F. Nielsen briquetting machines. New Allen-Bradley control systems were integrated by Taurus Power & Controls.

Want more content?

Wood Bioenergy is published and delivered 6 times per year tosubscribers worldwide. Readership includes corporate executives, mill ownership, mill management, logging contractors and equity venture interests. Wood Bioenergy is FREE to qualified readers.

Latest News

Michigan Company Opens AI Powered Biomass Facility In Grand Rapids

Michigan Company Opens AI Powered Biomass Facility In Grand RapidsWoodchuck, an AI-powered climate tech company focused on transforming wood waste into renewable energy, officially opened its flagship biomass processing facility in Grand Rapids, Mich. in early May....

Andritz Acquires LDX Solutions

Andritz Acquires LDX Solutions Andritz has acquired LDX Solutions, a provider of emission reduction technologies and related services in the North American industrial market, with annual revenues of about $100 million. This acquisition further strengthens Andritz’s...

Beaver Lake Renewables Begins Front-End Engineering Design

Beaver Lake Renewables Begins Front-End Engineering DesignOfficials with SunGas Renewables recently announced the start of front-end engineering design (FEED), marking the beginning of the final stage of development for its flagship project, Beaver Lake Renewable...

Pellet Fuels Institute Leads DC Fly-In

Pellet Fuels Institute Leads DC Fly-In Pellet Fuels Institute (PFI) spearheaded a fly-in on April 9, visiting 29 Congressional offices to discuss the wood pellet industry and PFI’s policy and regulatory agenda. A dozen member representatives from across the wood...

Darrell Smith To Lead USIPA As Executive Director

Darrell Smith To Lead USIPA As Executive Director The U.S. Industrial Pellet Assn. (USIPA) announced the appointment of Darrell Smith as its new Executive Director. Smith brings a wealth of association leadership experience and diverse industry expertise to USIPA. ...

Deere Joins Growth Energy

Deere Joins Growth Energy John Deere has joined Growth Energy, the U.S.’s largest biofuel trade association, joining a membership of operators and supporters of biomanufacturing facilities at the heart of America's bioeconomy, delivering a new generation of clean fuel...

Subscribe to Our Newsletter

Wood Bioenergy News Online hits the inboxes of subscribers in the wood-to-energy sectors.

Subscribe/Renew

Wood Bioenergy is published and delivered worldwide 6 times per year. Free to qualified readers in the U.S. Subscribers outside the U.S. are asked to pay a small fee.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative.