Inside this issue

From the Editors

Cover Story

In the News

- Enviva Reveals 2020 Implementation Plans

- ENCE Teams Up With SENER Again

- Drax Reaches Milestone Mark

- Drax Donates $30,000 Toward Relief Efforts

- PRODESA Will Supply Plants To Belarus

- Combilift Steps Up With Combi-Ventilate

- Northwest Deal Brings Parties To The Table

- Sun Bio Pulls Out Of Pulp Mill Project

- OSU’s Waring Shares Wallenberg Prize

Wood Bio Part Two: Projects, Air Emissions

This is part two of a three part series on the coverage of the Wood Bioenergy Conference & Expo held March 10-11 at the Omni Hotel at CNN Center in Atlanta. Part one appeared in the April issue. Part two here reviews the presentations of speakers in project development, air emissions technology and process maintenance.

Conveyor Considerations

Choosing The Right Conveyors For Biomass

Raw Materials Processing

The following companies provided editorial profiles to complement their advertisements throughout this issue:

- Bandit Industries

- Biomass Engineering & Equipment

- CW Mill Equipment

- Fulghum Industries

- Morbark

- Peterson Pacific

- Precision Husky

- Progress Industries

- Rawlings

- Vecoplan

- Vermeer

Product News

- Sugimat Will Supply Biomass Steam Boiler

- New Loggers-Truckers App Follows Loads

- Husqvarna Appoints President of North America Division

Find Us On Social

From the Editors

Years ago when it was introduced, the Obama Administration’s Clean Power Plan (CPP) from the Environmental Protection Agency (EPA) was quickly challenged in court on several fronts, the biggest being that the plan had over-reached by attempting to regulate energy policy through the Clean Air Act as opposed to sticking with environmental issues.

Yet now, with the Affordable Clean Energy (ACE) Rule from the Trump Administration being finalized to replace the CPP, rule-makers at the EPA have again wandered off course, this time ignoring the benefits of biomass in favor of emphasizing coal technology improvements in the pursuit of lower greenhouse gas emissions.

Scott Osbourn, principal with Trinity Consultants, covered the impact of the new rule during a presentation at the Wood Bioenergy Conference & Expo in Atlanta in March.

From Left: Rich Donnell, Editor-in-Chief; Jessica Johnson, Senior Associate Editor; Patrick Dunning, Associate Editor; David Abbott, Senior Associate Editor; Dan Shell, Senior Editor

The biggest difference between the two plans when it comes to biomass, he said, is the CPP only considers “inside the fence” systems and technologies that can be improved upon at a given facility, not any benefits that can be gained by using alternate fuel sources or closing facilities to shift capacity and feedstock.

A key term EPA uses is the best system of emission reduction (BSER), which gives operators guidance on how to best meet emissions reduction goals. However, benefits derived from biomass conversions or co-firing such as sustainability and carbon sequestration from replanting aren’t even considered.

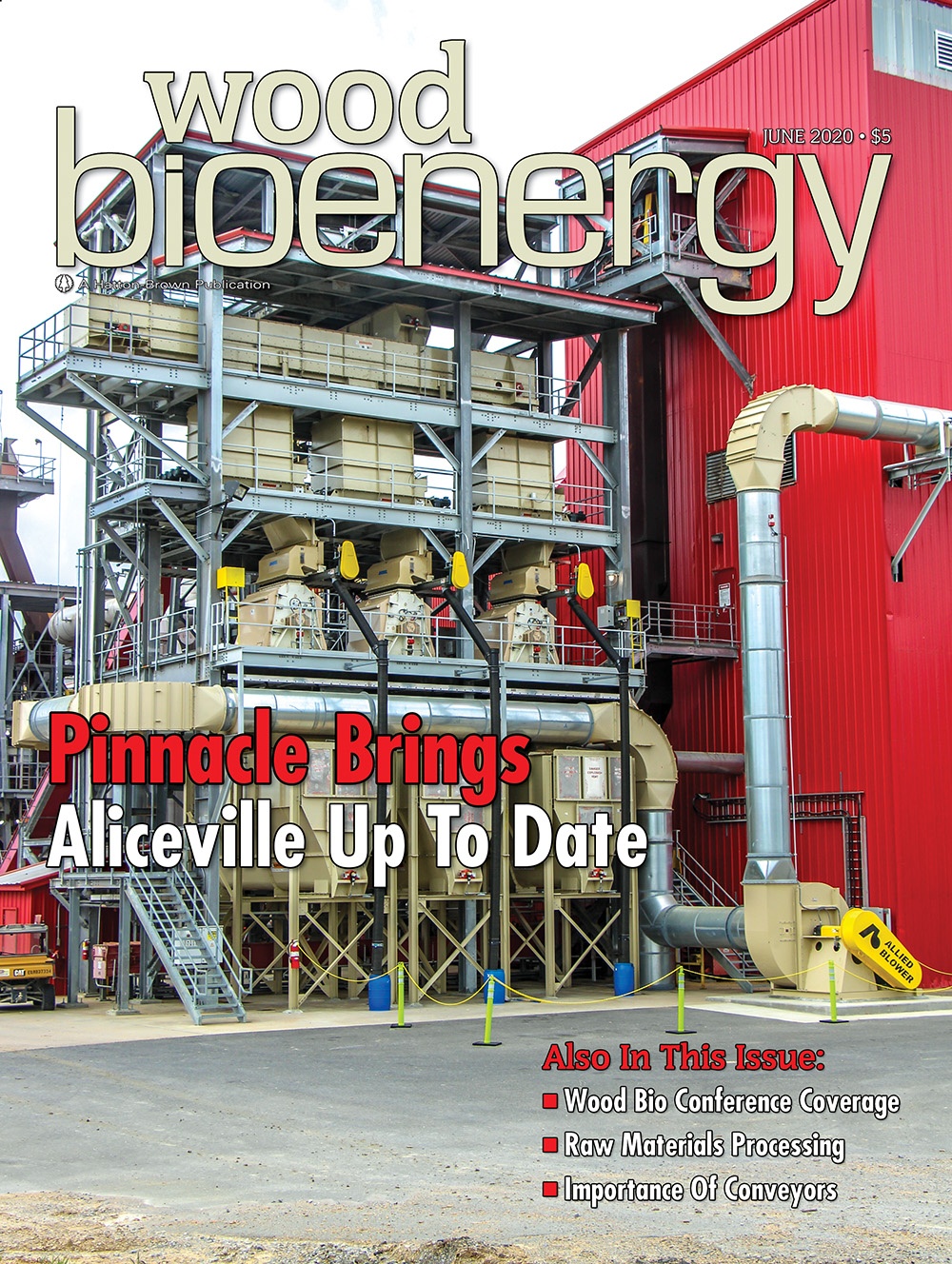

Cover Story

Article by Jessica Johnson, Senior Associate Editor, Wood Bioenergy

ALICEVILLE, Alabama – In late 2018, Pinnacle Renewable Energy announced the purchase of the majority of The Westervelt Co.’s wood pellet production facility in Aliceville, Alabama, while also entering into a long-term partnership agreement with Westervelt. For Pinnacle it represented a continuation of its focus on building partnerships with wood products companies who operate sawmills. Westervelt had long been known in the region for its high production sawmill and vast timberland holdings, when it built and started up a high production wood pellet mill at Aliceville in 2013.

Aliceville has four dry storage silos with capacities of 9,000 tons each.

Like other Pinnacle pellet plants, Aliceville’s raw material intake is dominated by sawmill residuals.

Last year, Pinnacle and Westervelt deepened their relationship and added Two Rivers Lumber into the partnership. The group announced they would build a greenfield wood pellet mill in Demopolis, Alabama, adjacent the new Two Rivers Lumber sawmill. Under the latest partnership agreement, Pinnacle owns 70% of the existing Aliceville and planned Demopolis facilities, while Westervelt retains 20%, and Two Rivers Lumber owns 10%.

Want more content?

Wood Bioenergy is published and delivered 6 times per year tosubscribers worldwide. Readership includes corporate executives, mill ownership, mill management, logging contractors and equity venture interests. Wood Bioenergy is FREE to qualified readers.

Latest News

Legacy Plant Converting To ‘Carbon Negative AI Factory’

Legacy Plant Converting To ‘Carbon Negative AI Factory’Specializing in developing smaller carbon footprints for AI operations, New York-based NewYork GreenCloud (NYGC) has acquired the closed Buena Vista Biomass Power facility in Ione, Calif., with plans to convert...

John King Chains Celebrates 100th Year

John King Chains Celebrates 100th YearJohn King Chains Group is celebrating its 100th anniversary in 2026. Established in Leeds, England in 1926, the enterprise began by producing plain pedestal bearings for coal mining pit tubs. Expansion came with the rapid...

Weyco Wood Fiber Will Feed Aymium Biocarbon

Weyco Wood Fiber Will Feed Aymium Biocarbon Weyerhaeuser Co. and Aymium entered a memorandum of understanding (MOU) to partner to produce and sell 1.5 million tons of sustainable biocarbon annually for use in metals production. As an initial stage of this partnership,...

Subscribe to Our Newsletter

Wood Bioenergy News Online hits the inboxes of subscribers in the wood-to-energy sectors.

Subscribe/Renew

Wood Bioenergy is published and delivered worldwide 6 times per year. Free to qualified readers in the U.S. Subscribers outside the U.S. are asked to pay a small fee.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative.