Sugimat To Supply Biomass Steam Boiler For Olive Extractor

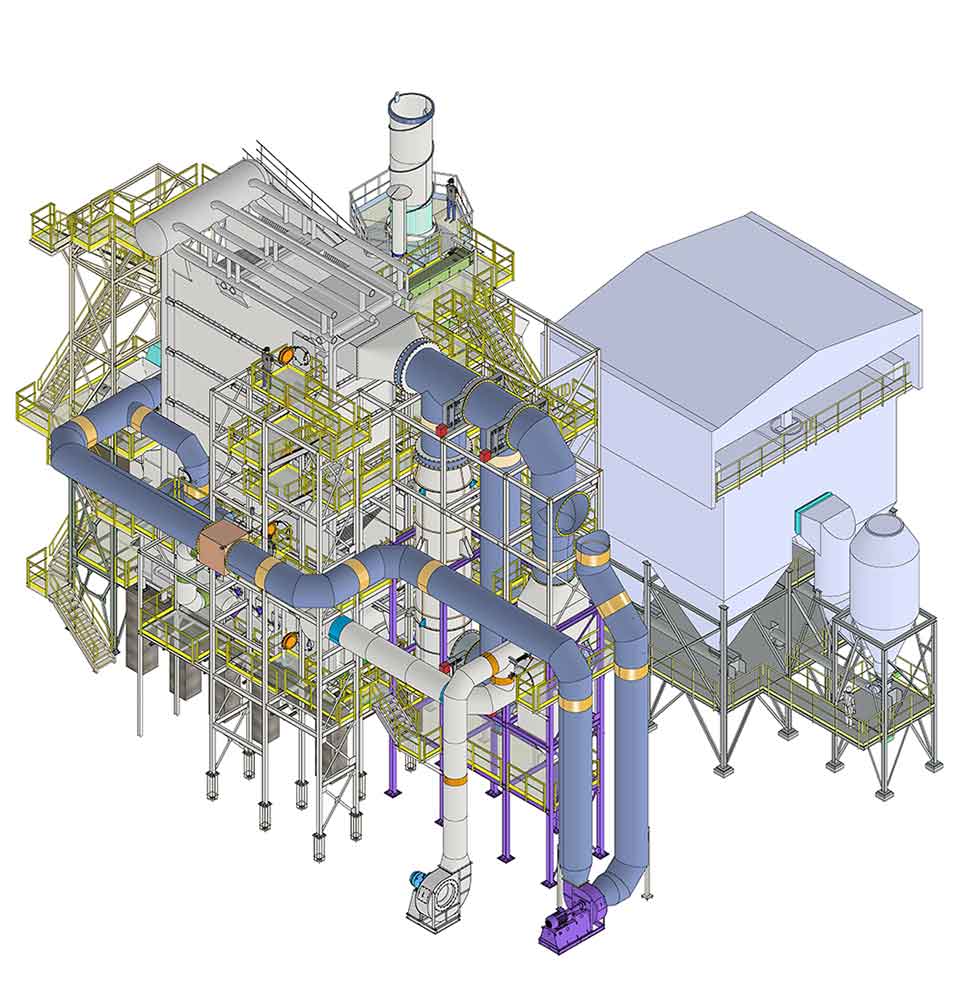

Olive marc extractor company Casa Alta–Sociedade Transformadora De Bagaços, LDA, has selected Sugimat for a new biomass-powered steam boiler and hot gas generator furnace for its productive process. Both machines will be fed with olive cake, a biomass product of the plant itself.

The biomass steam boiler will be used in the olive marc oil extraction process. It has a guaranteed availability of more than 8,000 h/year and will be specially designed to combust olive cake. This highly complex fuel requires a water-tube boiler design. Despite the technical difficulties in combustion, olive cake has a high calorific value and quality compared to other biomass fuels.

Sugimat will also provide the combustion system by means of a step grate, whose reliability and durability for this fuel. The hot gas generation chamber will also be fed with olive cake. These gases will be used in the dehydration of the alperujo coming from the oil mills. The gas generator will use the same model of reciprocating grate to also guarantee the availability of 8,000 h/year.

The process of decarbonization of the olive marc extractors is already an undeniable reality. Extractors using natural gas (methane) as a form of thermal energy will have to adapt. In Portugal, the olive marc extractors operate with oliva cake, but in Spain there is still a very important part of the olive marc extractors that operate with natural gas. Thanks to this type of equipment, olive marc extractors are getting closer and closer to carbon neutrality and those that operate with natural gas will no longer depend on price volatility, subject to the current or future geopolitical situation.

Latest news

Drax Supports United Way’s Latest Efforts

Drax Biomass donated $5,000 and essential water supplies to help evacuees in Northeastern Louisiana who were impacted by Hurricane Ida. The funds and supplies went to hurricane relief efforts driven by United Way of northeast Louisiana part of their “Embrace Louisiana” relief project.

Wood Pellet Mill In Adel Getting Closer

A proposed 450,000 metric tons per year industrial wood pellet mill to be built in Adel, Ga. is still an active project with nearly all of the pieces—including financing, equipment selection and air quality permit—in place, and construction expected to begin at mid-year 2022, according to Craig Whitlock, founder and…

Forest Service Backs Out Of Awarding Phase 2 Arizona Forests Restoration Contract; Uncertainties Persist For Novo Power

Anxious bidders for the Phase 2 contract that’s part of the federal 4 Forests Restoration Initiative (4FRI) seeking to treat and improve forest health conditions on more than 2.5 million acres across four Arizona national forests were told to wait a while longer after U.S. Forest Service (FS) officials abruptly…

Find Us On Social

Subscribe to Our Newsletter

Wood Bioenergy News Online hits the inboxes of subscribers in the wood-to-energy sectors.

Subscribe/Renew

Wood Bioenergy is published and delivered worldwide 6 times per year. Free to qualified readers in the U.S. Subscribers outside the U.S. are asked to pay a small fee.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative.