Sugimat To Supply Biomass Steam Boiler For Olive Extractor

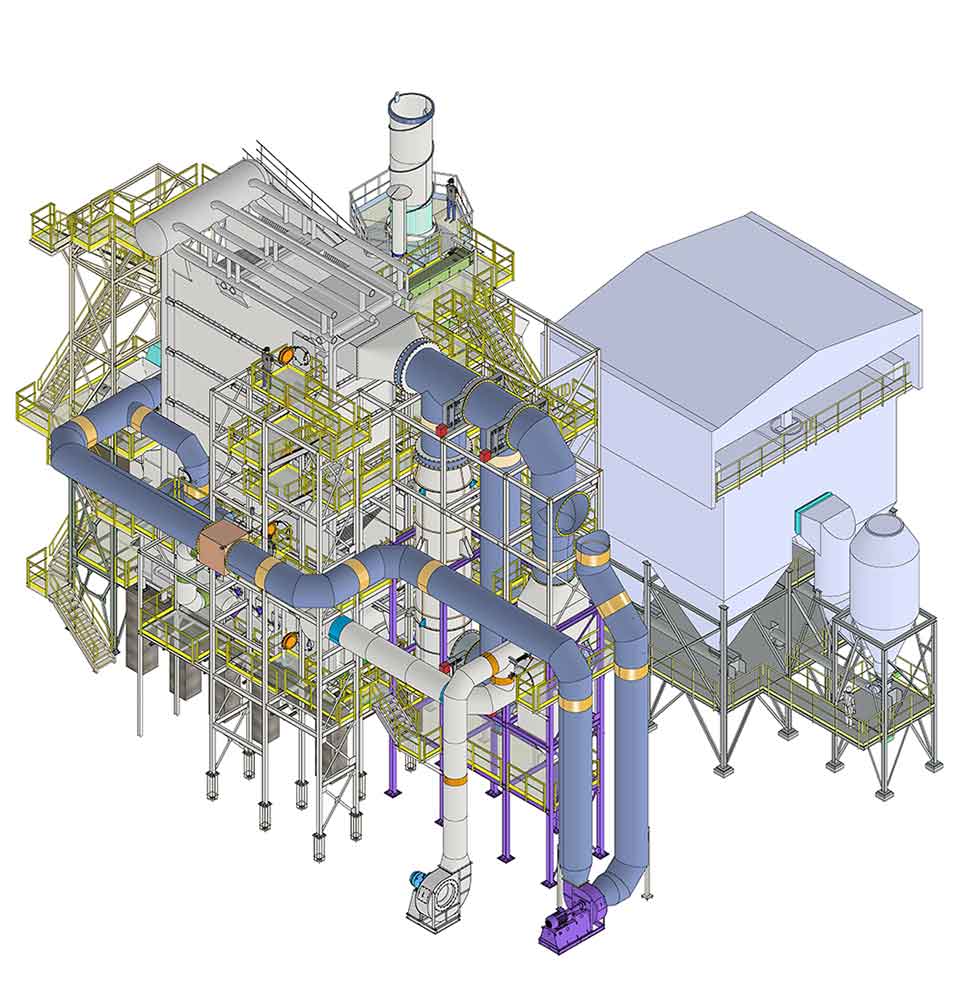

Olive marc extractor company Casa Alta–Sociedade Transformadora De Bagaços, LDA, has selected Sugimat for a new biomass-powered steam boiler and hot gas generator furnace for its productive process. Both machines will be fed with olive cake, a biomass product of the plant itself.

The biomass steam boiler will be used in the olive marc oil extraction process. It has a guaranteed availability of more than 8,000 h/year and will be specially designed to combust olive cake. This highly complex fuel requires a water-tube boiler design. Despite the technical difficulties in combustion, olive cake has a high calorific value and quality compared to other biomass fuels.

Sugimat will also provide the combustion system by means of a step grate, whose reliability and durability for this fuel. The hot gas generation chamber will also be fed with olive cake. These gases will be used in the dehydration of the alperujo coming from the oil mills. The gas generator will use the same model of reciprocating grate to also guarantee the availability of 8,000 h/year.

The process of decarbonization of the olive marc extractors is already an undeniable reality. Extractors using natural gas (methane) as a form of thermal energy will have to adapt. In Portugal, the olive marc extractors operate with oliva cake, but in Spain there is still a very important part of the olive marc extractors that operate with natural gas. Thanks to this type of equipment, olive marc extractors are getting closer and closer to carbon neutrality and those that operate with natural gas will no longer depend on price volatility, subject to the current or future geopolitical situation.

Latest news

USA Bioenergy, LP Sign Feedstock Letter Of Intent

USA Bioenergy, LP Sign Feedstock Letter Of IntentUSA BioEnergy (USABE) has signed a letter of intent with LP Building Solutions (LP) outlining plans to enter a long-term supply agreement for sustainably sourced wood fiber to support operations at USAB’s planned Texas...

Michigan Company Opens AI Powered Biomass Facility In Grand Rapids

Michigan Company Opens AI Powered Biomass Facility In Grand RapidsWoodchuck, an AI-powered climate tech company focused on transforming wood waste into renewable energy, officially opened its flagship biomass processing facility in Grand Rapids, Mich. in early May....

Andritz Acquires LDX Solutions

Andritz Acquires LDX Solutions Andritz has acquired LDX Solutions, a provider of emission reduction technologies and related services in the North American industrial market, with annual revenues of about $100 million. This acquisition further strengthens Andritz’s...

Find Us On Social

Subscribe to Our Newsletter

Wood Bioenergy News Online hits the inboxes of subscribers in the wood-to-energy sectors.

Subscribe/Renew

Wood Bioenergy is published and delivered worldwide 6 times per year. Free to qualified readers in the U.S. Subscribers outside the U.S. are asked to pay a small fee.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative.