Polytechnik, Andritz Among Suppliers For Europe’s Largest Industrial Torrefaction Plant

Finnish company Joensuu Biocoal Oy intends to produce renewable alternatives to fossil coal with a pioneering project that demonstrates a potential solution to the industrial push towards carbon neutrality, helping to reduce the environmental impact caused by fossil fuels while providing a renewable energy source.

Sustainably harvested forest residues are heated in a low-oxygen environment to produce a carbon-rich end-product. Torrefied biomass, or biocoal, has a higher energy density than traditional woody biomass, and is therefore more efficient to transport and easier to apply in existing coal power facilities or cement plants, due to its properties. It can be used in a range of applications including power generation, heating and in industrial processes as a carbon neutral alternative.

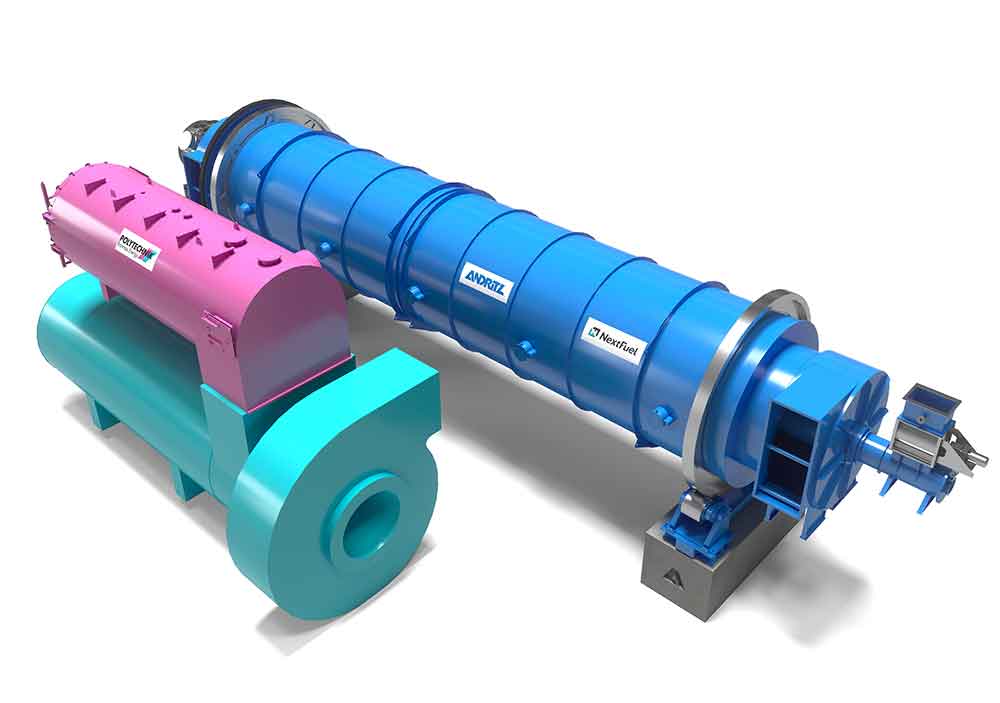

International technology Group Andritz will design, manufacture, and supply the reactor based on NextFuel AB technology, and Polytechnik will design, manufacture, and supply the lean gas burner and the technology for energy treatment and utilization, which will ensure a cycle-like use of the process energy. Construction is scheduled to start in mid-2023, and production to begin in late 2024.

The new bio-industrial plant will produce up to 60,000 tons of biocoal briquettes per year, utilizing sustainably sourced byproducts of local forestry, such as bark and low-grade biomass, which show the enormous potential for CO2 savings of large-scale defossilization technology.

Latest news

Shavings Operation Telfair Forest Products Eyes Torrefaction Facility

Shavings Operation Telfair Forest Products Eyes Torrefaction FacilityTelfair Forest Products announced it is constructing a torrefaction facility at its operations in Lumber City, Ga. Telfair will implement biomass torrefaction technology from TSI. Telfair Forest...

Chris Brown Assumes Role As Mid-South President

Chris Brown Assumes Role As Mid-South President Mid-South Engineering recently bid a happy retirement to President Marc Stewart after 27 years with the company. "Leaving my daily interactions with this team leaves a Mid-South-logo-shaped hole in my heart," Stewart...

Con-Vey Expands Operations In Oregon

Con-Vey Expands Operations In OregonCon-Vey is planning an expansion of its operations with the acquisition of approximately 15 additional acres, including 150,000 sq. ft. of manufacturing space. Strategically located with both highway and freeway access, and just 6.3...

Maine Biofuels Plant Permitting In Process

Maine Biofuels Plant Permitting In ProcessOfficials with the Castlerock Biofuels plant in Millinocket, Maine say permitting is in process and much of the engineering complete for the “biocrude” manufacturing plant that will produce 20 million gallons of institutional...

Find Us On Social

Subscribe to Our Newsletter

Wood Bioenergy News Online hits the inboxes of subscribers in the wood-to-energy sectors.

Subscribe/Renew

Wood Bioenergy is published and delivered worldwide 6 times per year. Free to qualified readers in the U.S. Subscribers outside the U.S. are asked to pay a small fee.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative.