Inside this issue

From the Editors

Cover Story

In the News

Black Pellets Plant Finds New Life

Next Enviva Mill May Be Lucedale

Torrefaction Plant Begins Construction

Ligna Hannover Offers Multiple Events

Pellet Markets

2018 Was A Banner Year

Wood Bio Guide

Products, Manufacturers

Product News

Morbark Acquires Denis CIMAF

Flamex Offers Advanced Detector

Find Us On Social

From the Editors

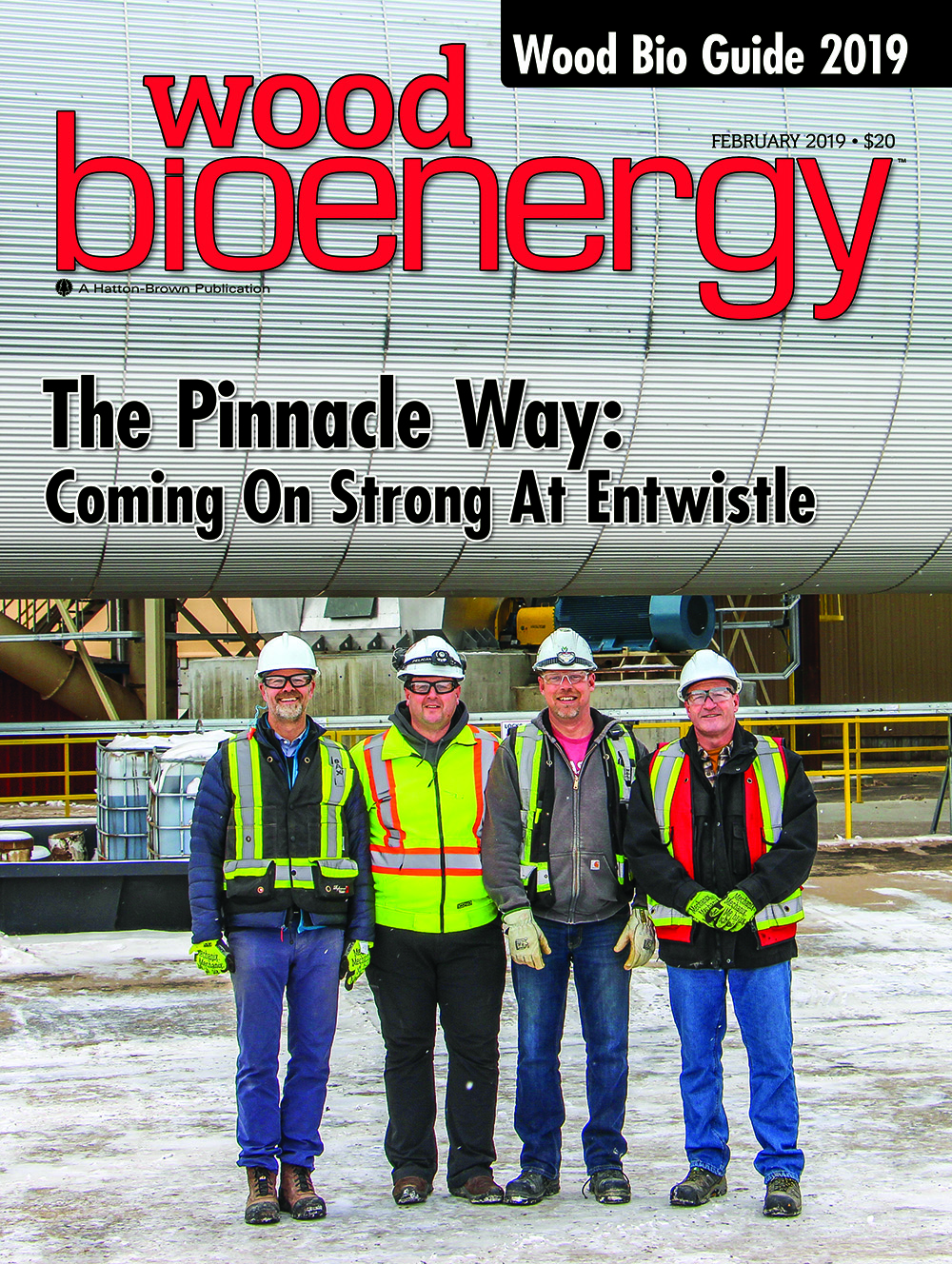

How does one of us end up in a wood yard with an 8° “wintry” mix swirling about? Even now when our editorial staff has a combined 145 years with our collective boots on the ground around the world, there are still some situations that surprise us. Or, in this case quite literally numb us.

When Pinnacle Renewable Energy first appeared on the scene, Wood Bioenergy watched as the company grew in British Columbia and continued to add plant after plant to its growing roster. Since 2013 alone, Pinnacle has brought three plants on-line and taken over daily operations and the majority stake of a fourth. When CEO Rob McCurdy spoke at the Wood Bioenergy Conference in Atlanta last April, the Pinnacle story began to really capture WB’s resident industrial pellet specialist Jessica Johnson’s attention.

Then, as we began to discuss the plants and profiles that will fill Wood Bioenergy’s pages in 2019, Pinnacle’s startup in Entwistle, Alberta was first up. Our top dog Rich Donnell promptly asked the staff who wanted to make the trip to northern Alberta in the winter. Everyone immediately looked at Jessica, knowing she would volunteer. And she did, to the peals of laughter from the rest of the staff. In the weeks leading up to the trip, regular forecast emails circulated, and bits of warm clothing were dropped on her desk.

For Jessica it was a no-brainer and she jumped at the chance to go to northern Alberta in the winter—probably because she wasn’t thinking about the fact that it would be “way” below freezing. But that’s our Jessica; she doesn’t always think about the weather of the places she visits. She visited Drax’s newest startup in central Louisiana in mid-July when it was a frosty 105°. A little sweat never hurt anyone.

From Left: Jessica Johnson, Associate Editor; Dan Shell, Managing Editor; Jay Donnell, Associate Editor; Rich Donnell, Editor-in-Chief; DK Knight, Executive Editor; David Abbott, Senior Associate Editor

Of course, when she made a frantic phone call back to the WB office in Montgomery, Alabama one morning in early December, the rest of the editors did nothing but laugh again. The scene: A car so deeply covered in snow it was not drivable until hit with a shovel. A temperature gauge reading a brisk and blustery 8° Fahrenheit with a forecast showing a high of 10° for the day. The phone call, which was put on speaker, had a bit of a shriek-like feel to it: “Why did I think this was going to be a good idea. It’s way too cold! I am wearing two pairs of pants and I still can’t feel my toes.” Rich responded, in his usual unsympathetic manner: “Don’t get your tongue stuck to the catwalk.”

But as the landscape of the 400,000 metric ton facility, bathed in a sheet of wintry mix of snow and ice, came into her camera’s focus a few hours later, she proudly knew she had the perfect shot, about the same time her nose had become perfectly numb.

Once again, Wood Bio had gone the distance.

Cover Story

ENTWISTLE, Alberta

Some pellet producers have successfully used a “cookie cutter” approach to building successive plants. But for Canadian producer Pinnacle Renewable Energy, one size doesn’t really fit all nine. Following a March 2018 startup, Pinnacle’s Entwistle plant is now hitting its stride in the commissioning phase with production records being set regularly according to Plant Manager Marcus Ziesmann. Pinnacle Entwistle is the company’s first outpost in the western province of Alberta, targeting production of 400,000 metric tons of industrial pellets annually.

Senior Vice President of Operations Scott Bax says that the key to Pinnacle’s success has been right-sizing their plants for the areas in which they operate—taking the fiber basket and logistics into the equation. Almost every one of the nine plants is a different size. Technologies vary in the plants as well. For example, in the 125,000 metric ton Smithers plant, Pinnacle opts to run a bed dryer from Stela. In Entwistle, Pinnacle uses a single large rotary dryer from TSI.

“When we look at where we put our facilities,” Bax continues, “we look at everything from how it can be integrated with local communities, the overall footprint of the plant and the size of the site to the proximity of local sawmills, optimizing our selections based on all those variables.”

“As our President and COO Leroy Reitsma says, ‘when I see a large pile of residuals, I see an opportunity.’ We were able to come in and enter into some long-term deals for the residuals. The sawmills had been stockpiling a fair bit,” Bax adds.

Entwistle runs a unit train concept to get pellets to the Port of Prince Rupert, BC – filling 90 rail cars before dedicated locomotive hauls them back and forth.

There are a lot of variables, given that just in 2018, in addition to the startup in Entwistle, Pinnacle started up a partnership pellet plant in Smithers, BC and purchased the majority of the Westervelt pellet plant in Aliceville, Alabama. Stated capacity for the nine facilities is 2.2 million metric tons. Entwistle represents Pinnacle’s first big leap into monster production numbers.

Location certainly sets Entwistle apart, literally—over 1,350 km separate the facility from Pinnacle’s Westview terminal at the Port of Prince Rupert, BC and more than 1,000 km separate it from Pinnacle corporate headquarters in Richmond, BC. The hamlet of Entwistle isn’t that different from the other locations of Pinnacle plants, Bax admits, saying at the heart and soul of what drew them there was a surplus of sawmill residuals that were left without a market following the slowdown of oil and gas production in the region.

Like all other Pinnacle pellet plants, Entwistle uses 100% softwood (mainly lodgepole and jack pine) sawmill residuals: sawdust as well as long, thin, fat shavings, which Bax calls “curly qs” and some bark material. The plant does not consume chips because, according to Bax, there’s already a natural home for them with the pulp facilities in the surrounding area and it makes little sense for Pinnacle to attempt a disruption there.

Dry fiber storage tent adjacent the hammermill building.

Pinnacle mills collectively operate the world’s largest number of Andritz pelletizers.

Want more content?

Wood Bioenergy is published and delivered 6 times per year tosubscribers worldwide. Readership includes corporate executives, mill ownership, mill management, logging contractors and equity venture interests. Wood Bioenergy is FREE to qualified readers.

Latest News

USA Bioenergy, LP Sign Feedstock Letter Of Intent

USA Bioenergy, LP Sign Feedstock Letter Of IntentUSA BioEnergy (USABE) has signed a letter of intent with LP Building Solutions (LP) outlining plans to enter a long-term supply agreement for sustainably sourced wood fiber to support operations at USAB’s planned Texas...

Michigan Company Opens AI Powered Biomass Facility In Grand Rapids

Michigan Company Opens AI Powered Biomass Facility In Grand RapidsWoodchuck, an AI-powered climate tech company focused on transforming wood waste into renewable energy, officially opened its flagship biomass processing facility in Grand Rapids, Mich. in early May....

Andritz Acquires LDX Solutions

Andritz Acquires LDX Solutions Andritz has acquired LDX Solutions, a provider of emission reduction technologies and related services in the North American industrial market, with annual revenues of about $100 million. This acquisition further strengthens Andritz’s...

Subscribe to Our Newsletter

Wood Bioenergy News Online hits the inboxes of subscribers in the wood-to-energy sectors.

Subscribe/Renew

Wood Bioenergy is published and delivered worldwide 6 times per year. Free to qualified readers in the U.S. Subscribers outside the U.S. are asked to pay a small fee.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative.