Inside this issue

FROM THE EDITORS

COVER STORY

IN THE NEWS

- Bandit Names Davis CEO/President

- Peak Renewables Proceeds With Project

- Weyerhaeuser Does Carbon Credit Sale

- FPIC At La Tech Receives Donation

- Endowment Welcomes New Board Members

- Graanul Invest Names Director of Sales

- Biden Focuses On Old-Growth

- RENOVA Announces Start of Operations

- GA Ports Approves Inland Rail Terminal

- Top Wood Jobs Changes Ownership

- SPI names Hoover VP of Resources

Wood Bio Conference 'Energy That Works'

“I’m more impressed with this lineup of speakers than any we’ve had in the history of our event,” comments Rich Donnell, Co-Chairman of the eighth Wood Bioenergy Conference & Expo, which will be held Tuesday-Wednesday, March 12-13, at the Omni Atlanta Hotel at Centennial Park in downtown Atlanta, Georgia.

PRODUCT NEWS

- Steel Dynamics Orders Biocarbon Plant

- Air Burners Introduces BioCharger

Find Us On Social

From the Editors

A Closing Door Opens Another

For the editors of Wood Bioenergy, all who grew up and still enjoy watching sports, equally divided 50/50 in terms of collegiate allegiances-the War Eagles and the Roll Tiders-winter means gearing up for basketball season, while regrouping from a typically disappointing football season for Auburn and typically triumphant one for Alabama. Except this year is different.

Alabama suffered a somewhat devastating blow in a College Football Playoff Semi-final loss, and then the absolute worst news an Alabama fan could have heard broke. Legendary Coach Nicholas Lou Saban, Jr. has retired from coaching college football. Managing Editor Jessica Johnson’s nine-year-old son Alex, upon hearing the news, immediately started sobbing, and locked himself in the bathroom. It is still a time of mourning in the Johnson house.

But, as it relates to the wood bioenergy industry, how can we look at the retirement announcement of Saban and make any sort of correlation? Well, it’s easy—when one industry titan or major project is struggling, it gives way for new players, new technologies, and new projects. One of those new projects is Delta Biofuel’s pellet plant in Jeanerette, La. which will take bagasse as its feedstock and make high-quality pellets. Hear Tyler Player, whose company PDI is acting as the EPC contractor (and dryer supplier) on the project, discuss it in detail at the upcoming Wood Bioenergy Conference & Expo, March 12-13, in Atlanta, Ga., as one of the featured presentations.

Perhaps one of the most interesting of the new projects is the newly announced development of Drax’s new-build BECCS plants to be located both in North America and abroad, an effort that will be led by senior energy infrastructure expert, Laurie Fitzmaurice, appointed as President for this new U.S.-headquartered entity.

UK-based Drax Group intends to establish this new independent business unit to focus on becoming the global leader in delivering large-scale and high-integrity carbon removals. Working with coalition partners, the new business will offer a compelling proposition that combines Drax’s expertise in BECCS with the latest climate science and it will have an ambitious goal to remove at least 6 million tons of CO2 from the atmosphere annually. The business will be operationally separate within the Drax Group and headquartered in Houston, Texas. Led by Fitzmaurice, who has nearly 30 years of experience in business development around the world, most recently for Amazon Web Services, Drax intends to formally launch this new entity later this year.

From Left: Jessica Johnson, Managing Editor; Dan Shell, Senior Editor; Rich Donnell, Editor-in-Chief; David Abbott, Senior Associate Editor

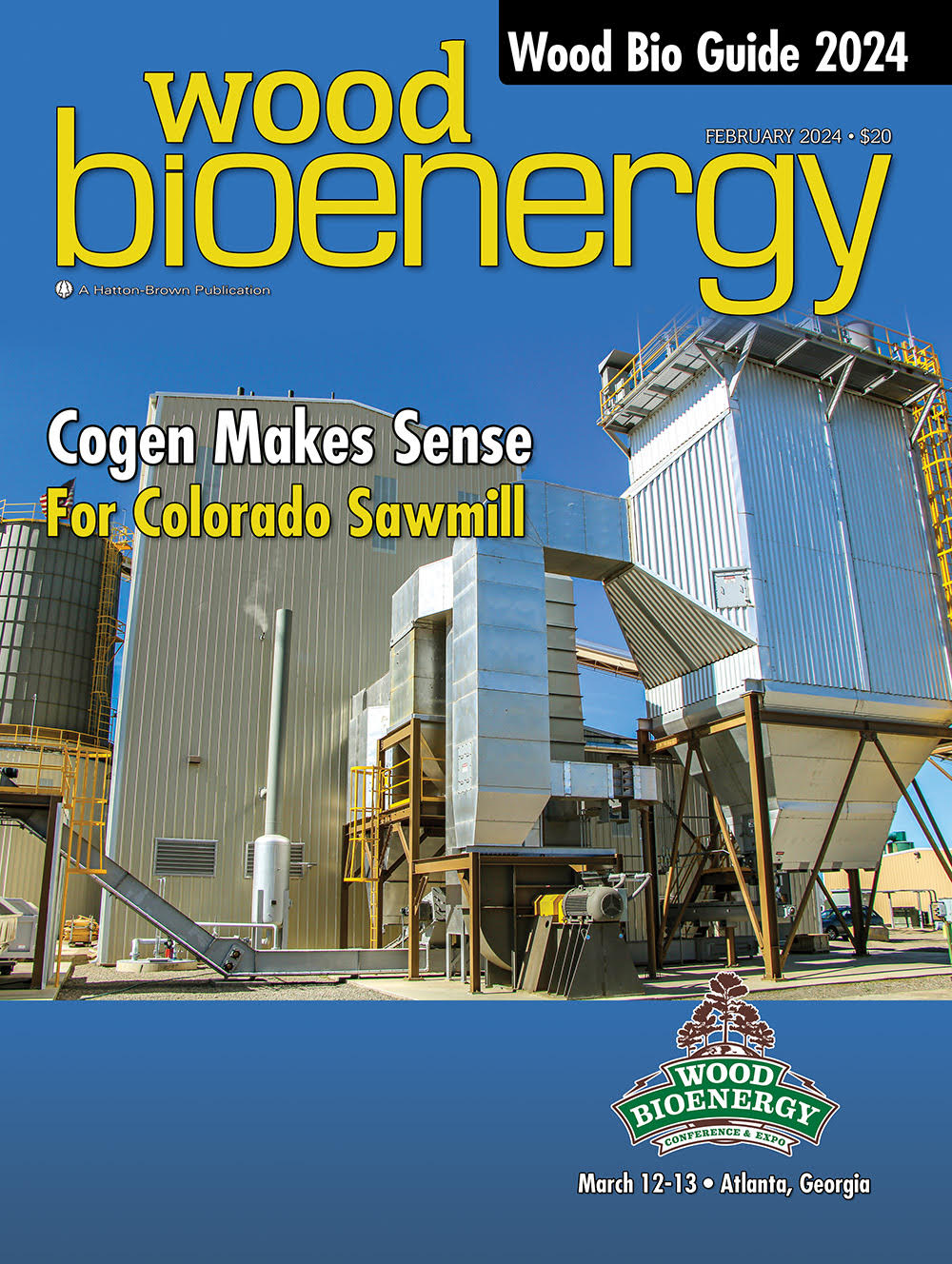

Cover Story: Cogen Makes Sense For Colorado Sawmill

Article by Dan Shell, Senior Editor, Wood Bioenergy

MONTROSE, Colorado – Reducing energy costs while becoming more self-sufficient and investing in operational solutions, the Neiman family’s Montrose Forest Products sawmill has done both with the installation of a new 1.25 MW cogeneration plant that’s providing 40% of the mill’s electricity needs while fully utilizing its residual stream.

“We had been looking hard at a pellet mill,” says Montrose Forest Products General Manager Mike Kusar. And Neiman does operate a pellet plant at its Spearfish, SD sawmill. However, a biomass-powered cogeneration plant provided a better solution for the Montrose mill at its western Colorado location for a couple of big reasons.

In the area, getting rid of residuals can be a major challenge for a larger operation like Montrose Forest Products, which produces approximately 80MMBF annually. There’s no large pulp-paper mill, composite board, or pellet plant in the region that consumes significant volume and serves as a large market for chips and sawdust. Kusar notes the sawmill has long processed dead and dying trees from the beetle-killed forests of Colorado. This, in turn, has increased its residual output.

The overall energy situation in the region also led the mill to seek more self-sufficiency. An existing gas-fired boiler needed upgrading anyway for the increased kiln activity (and is currently kept in place as a backup). But even more important, the region’s natural gas infrastructure can be stressed during extended or extreme cold spells, and the mill’s kilns had to be taken off-line for several days in a recent winter due to the extremely high price of natural gas supplies. Electricity costs are also on the rise.

“We have high electricity and natural gas costs here, and (the new plant) will help offset those costs,” says Allen Satur, cogen plant supervisor. “But the project really came from the necessity of moving huge piles of byproducts.”

Project

Mill personnel made the decision to go with the cogen plant in mid-2021, and the facility was in full construction mode a year later.

To make it happen, Montrose Forest Products turned to Wellons, which provided a 50,000 PPH boiler coupled with a 1500 KW turbine generator from Siemens. The package included two (2) A-30-40 fuel storage bins, fuel delivery and handling equipment, including the truck reclaimer—plus a Columbia Water water treatment facility. The plant is fitted with a Wellons-built electrostatic precipitator for pollution control. The project cost is roughly $16 million.

Put in as a mostly turnkey package from Wellons, the plant includes two 80 ft. silos that store boiler fuel, roughly three days’ worth. The mill is using live bottom trailers to move collected material—mostly sawdust and chipped mill residuals—to the infeed area reclaimer that feeds a 300 ft. conveyor leading to the two silos.

According to Satur, the project has gone relatively smoothly. Wellons has provided plenty of on-site assistance and is always on call if needed, he adds. It was quite a startup crew: Satur had no formal boiler training; one of the crew members did, but no one had any wood-fired boiler experience. Much of his early time was spent researching and learning.

The selection of Satur, an 11-year employee who was working in the rolling stock shop, may have raised some eyebrows in the organization, but Kusar knew he had the right guy to oversee the new cogen system and process. “Allen’s taken the project by the horns, and he’s done a great job from the time we put the first piling in the ground,” Kusar says.

Aside from a late discovery that the new plant’s water pressure requirements meant the installation of new water lines and taps, there have been no real big surprises, Satur says.

Startup challenges include standard programming and learning curve issues, he adds. “We had some programming issues and some repeat problems on certain things, and Wellons has been great about helping us find solutions,” Satur says.

Want more content?

Wood Bioenergy is published and delivered 6 times per year tosubscribers worldwide. Readership includes corporate executives, mill ownership, mill management, logging contractors and equity venture interests. Wood Bioenergy is FREE to qualified readers.

Latest News

Michigan Company Opens AI Powered Biomass Facility In Grand Rapids

Michigan Company Opens AI Powered Biomass Facility In Grand RapidsWoodchuck, an AI-powered climate tech company focused on transforming wood waste into renewable energy, officially opened its flagship biomass processing facility in Grand Rapids, Mich. in early May....

Andritz Acquires LDX Solutions

Andritz Acquires LDX Solutions Andritz has acquired LDX Solutions, a provider of emission reduction technologies and related services in the North American industrial market, with annual revenues of about $100 million. This acquisition further strengthens Andritz’s...

Beaver Lake Renewables Begins Front-End Engineering Design

Beaver Lake Renewables Begins Front-End Engineering DesignOfficials with SunGas Renewables recently announced the start of front-end engineering design (FEED), marking the beginning of the final stage of development for its flagship project, Beaver Lake Renewable...

Pellet Fuels Institute Leads DC Fly-In

Pellet Fuels Institute Leads DC Fly-In Pellet Fuels Institute (PFI) spearheaded a fly-in on April 9, visiting 29 Congressional offices to discuss the wood pellet industry and PFI’s policy and regulatory agenda. A dozen member representatives from across the wood...

Darrell Smith To Lead USIPA As Executive Director

Darrell Smith To Lead USIPA As Executive Director The U.S. Industrial Pellet Assn. (USIPA) announced the appointment of Darrell Smith as its new Executive Director. Smith brings a wealth of association leadership experience and diverse industry expertise to USIPA. ...

Deere Joins Growth Energy

Deere Joins Growth Energy John Deere has joined Growth Energy, the U.S.’s largest biofuel trade association, joining a membership of operators and supporters of biomanufacturing facilities at the heart of America's bioeconomy, delivering a new generation of clean fuel...

Subscribe to Our Newsletter

Wood Bioenergy News Online hits the inboxes of subscribers in the wood-to-energy sectors.

Subscribe/Renew

Wood Bioenergy is published and delivered worldwide 6 times per year. Free to qualified readers in the U.S. Subscribers outside the U.S. are asked to pay a small fee.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative.