GreCon’s New Intelligent Extinguishing Module (IEM)

SPONSORED CONTENT PROVIDED BY FAGUS GRECON

Common causes of fires in wood bioenergy production are heat, sparks, embers, and hot particles. A key area that needs to be protected is when material moves out of the dryers. One of the most efficient measures to prevent fire or dust explosion is the early identification of the ignition source so it can be extinguished quickly.

GreCon Spark Detection & Extinguishing Systems provides excellent preventive protection; it does not wait for an actual fire or dust explosion to erupt. The GreCon system prevents the development of these hazards by early detection and elimination of the ignition source.

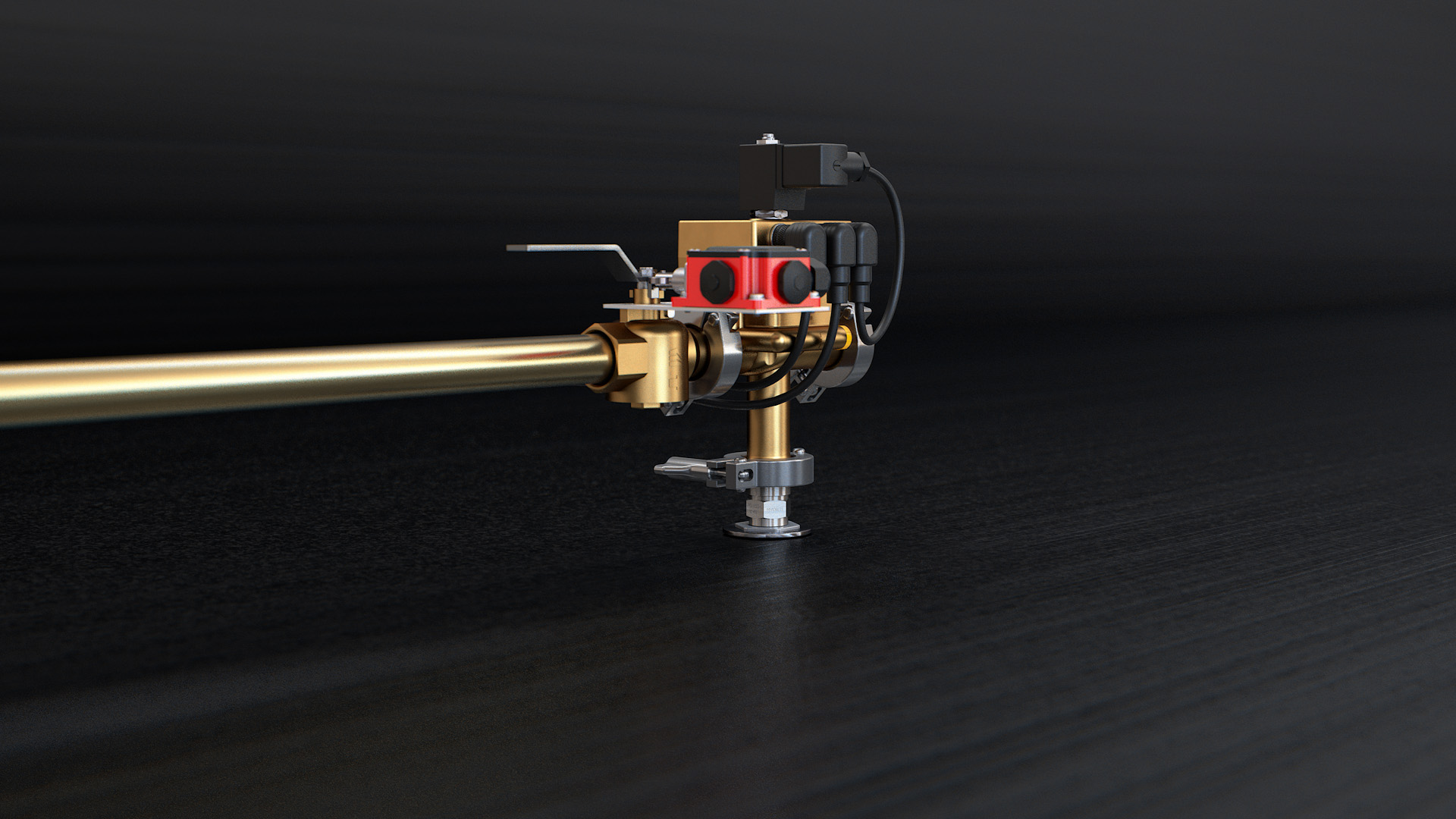

Now there is also an even better “smart” extinguishing option. The New GreCon Intelligent Extinguishing Module (IEM) reliably extinguishes sparks while also monitoring early wear recognition. The new smart GreCon IEM has sensors integrated into the extinguishing module to detect the wear of your nozzles while also monitoring low pressure flow to the nozzles. Thus, increasing plant and system availability with efficient planning of maintenance to reduce downtime. In addition, to monitoring flow to the nozzle the system will also detect and recognize when micro leaks are occurring with a nozzle. Thus, allowing for repair of defective nozzles before they become a problem. The IEM system can also add a built-in integrated frost monitoring component into the system, for greater operational safety. Another benefit of the system may be less intelligent, but it is certainly smarter for saving time while maintaining the system. This is the non-tool needed quick release latches that are built into the system to allow for changing a nozzle in less than a minute.

The IEM builds upon Fagus GreCon’s existing knowledge of intelligent systems, which includes the intelligent DLD 1/9 Spark Detector. The DLD 1/9 also offers additional protection to industries with intelligent detection technology (IDT). IDT not only identifies hazardous moving ignition sources before a fire breaks out, but the DLD 1/9 detector is also able to differentiate between dangerous sparks or harmless incidence of extraneous light due to leaky/damaged pipes or an opening of an inspection flap.

Latest News

Malwa Impresses Graanul Invest

Valga Puu, a forestry company of Graanul Invest, has acquired two Malwa harvesters that will enable better maneuvering in forest thinnings and prevent ground damage. The lightweight, nimble harvesters can…

Georgia Power Seeking Biomass Plant Bids

Georgia’s Public Service Commission recently voted to allow major utility Georgia Power to solicit bids for a new 50MW biomass-powered power plant. The move is part of a Georgia Power effort to purchase more energy from a variety of sources as the company seeks to retire some of its older power generating facilities. In addition to biomass, the utility is also looking at streams turbine, battery energy storage…

Cousineau Plans Rebuild After May Fire

The owner of Cousineau Forest Products, Randy Cousineau, says the company is rebuilding after a late May fire at its wood processing facility in Henniker, NH. According to Cousineau, the fire caused $500,000 in damages at the plant that produces playground surfacing materials, biomass fuel, chips and bark mulch. The facility has brought in mobile equipment to continue some operations during a rebuild that’s complicated…

Find Us On Social

Subscribe to Our Newsletter

Wood Bioenergy News Online hits the inboxes of subscribers in the wood-to-energy sectors.

Subscribe/Renew

Wood Bioenergy is published and delivered worldwide 6 times per year. Free to qualified readers in the U.S. Subscribers outside the U.S. are asked to pay a small fee.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative.